Hét jótanács, hogy ne szálljanak el egy építőipari beruházás költségei

Seven Tips to Keep Construction Project Costs Under Control

The construction industry is changing rapidly: cost pressure is increasing, while new technologies and sustainability requirements are reshaping projects. Cost reduction is not a single trick but a disciplined, lifecycle-oriented project management approach. Accurate quantities, well-prepared tender documentation, risk readiness and data-driven planning together balance construction costs, time and, of course, quality. The next step lies in increasing BIM detail, expanding AI capabilities and applying contractual discipline even more consistently. Here are seven tips from CÉH zRt. on how to prevent project costs from spiralling out of control.

The life of construction projects is defined by the cost–quality–time triangle, completed—especially in industrial environments—by technological requirements. The task of project management is to create and maintain this balance. Its key tools are precise process planning and the consistent management of deviations, both of which are crucial factors influencing final cost.

Overly short deadlines may seem to save money, but they may force the use of more expensive construction technologies or a larger equipment fleet. Typical sources of cost fluctuation include prolonged schedules, sudden price or exchange rate changes and material shortages. Preparing for these with alternative technical solutions and reserve resources is essential. The coordinated management of cost, schedule and technical scope changes reduces both the likelihood and the scale of cost overruns.

CÉH zRt.’s project management approach is systemic, covering the entire service chain: project preparation, tendering, design management, design review, technical supervision, cost tracking, financial calculations and project closure. Expertise, cost analysis, costing and price estimation form a key competency—particularly in a field that remains under-regulated. The company sees cost optimisation not as a one-off task but as a continuous process. During preparation, it defines a precise programme, assigns costs to it, and manages the two streams in alignment.

During design, cost differences between the available options are calculated in parallel, and the best solution is selected. This practice aligns with the principles of value engineering—optimising cost while preserving function.

Daily cost tracking is supported by specialised software. In large projects such as automotive investments, the Abux system is used, where hundreds of items move monthly. In smaller projects, Excel remains a simple and effective tool, complemented by in-house developments.

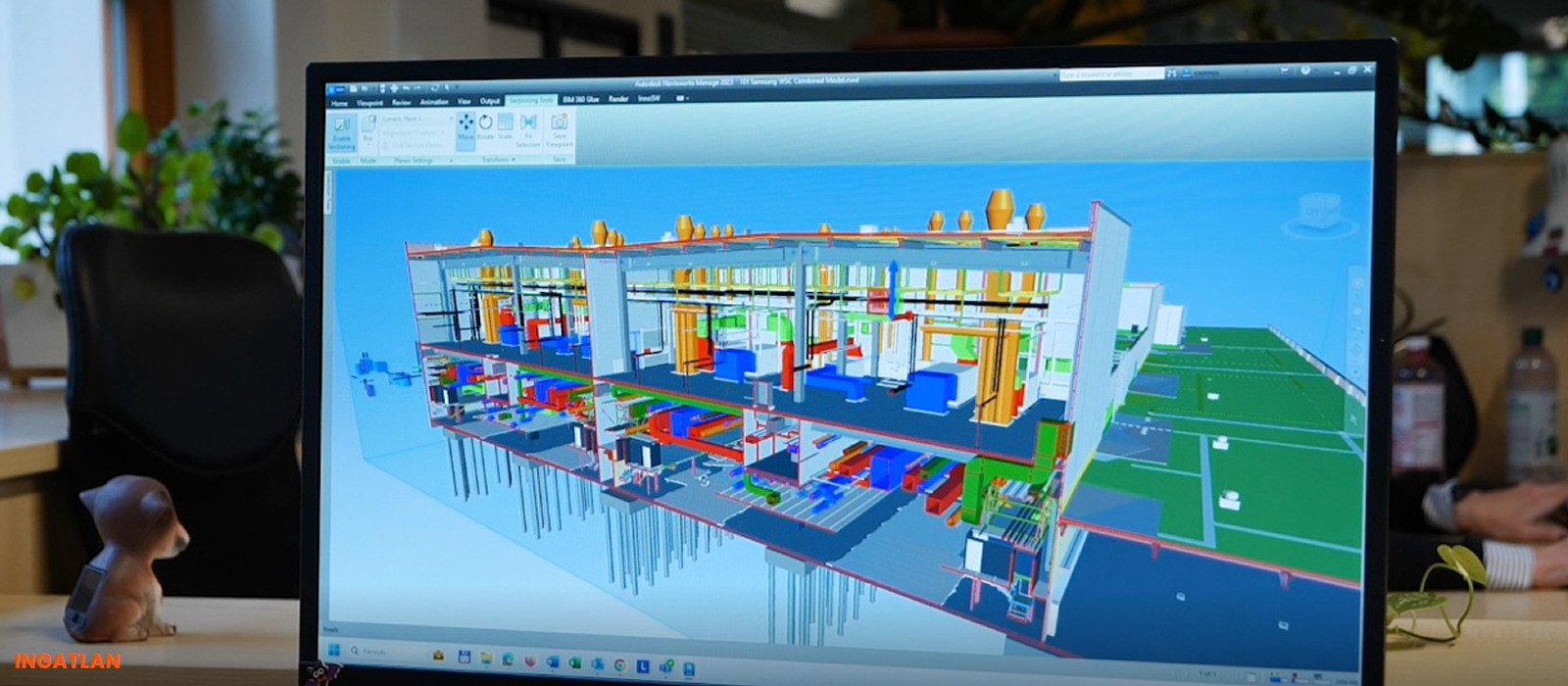

BIM and AI: Data-Driven Decisions from Quantities to Tendering

At CÉH, Building Information Modelling (BIM) enables ever more detailed and accurate project models. Accurate quantity take-off is the foundation of reliable pricing, which is why the company trains its colleagues in AI usage: automatic quantity extraction and rapid calculation of component counts directly improve cost estimation. Parametric design enables the quick comparison of thousands of variations, from which engineers can select the best alternative.

In tendering, the accuracy of quantity schedules is of decisive importance. BIM-based take-offs and parallel cost calculations support this process. During tender evaluation, the weights of quality, price and schedule are adjusted to reflect the project’s actual objectives. Reliability and capacity are just as important selection criteria as price. Clear contractual structures and well-defined expectations reduce the number of variations and therefore the cost risk.

A well-prepared tender process and its documentation secure the project’s future. The goal is to select contractors who deliver reliably, in accordance with the technical scope and at a realistic price. Unusually low bids also carry risks, often leading to difficult-to-manage problems later.

What to Watch Out For?

Experience shows that project preparation determines later costs. It is important to clarify client expectations repeatedly and align the design with them. Precise quantity calculation and disciplined tender preparation are the best safeguards for staying within budget. Overly tight deadlines may force expensive solutions, so schedules must be based on realistic capacities. Digital tools—BIM and AI—are not ends in themselves: the goal is faster decision-making and error prevention.

Seven Tips for Cost Reduction

1. Align project scope and budget already in the preparation phase.

2. Track technical, schedule and cost changes in a single, up-to-date system.

3. Use BIM and parametric design to refine quantities.

4. Prepare a clear, transparent tender and select a reliable contractor.

5. Prepare for material and exchange rate risks with alternative solutions.

6. Base the schedule on real capacities—avoid cost-increasing rush.

7. Use specialised software (e.g. Abux) for detailed cost tracking.

MOL Tower, BMW Plant Debrecen, Matild Palace: Tools in Practice

Throughout its 35-year growth, CÉH zRt. has delivered outstanding projects.

The reconstruction of the Hungarian State Opera integrated modern technologies into a building originally inaugurated in 1884: a four-storey stage machinery system, state-of-the-art lighting and a 1,000+ seat auditorium were realised.

The renovation of Matild Palace created a 133-room luxury hotel with conference rooms, a spa, restaurants and a heritage café. The project demonstrated that historic environments require disciplined scheduling, careful tendering and strict cost control.

In Debrecen, the BMW plant stands out for its scale: 4,000,000 m² of land and 650,000 m² of buildings, with thousands of contributors. The project was preceded by a nine-month tendering process and followed by the establishment of an on-site engineering office of more than 100 people. In investments of this size, the balance of cost–time–quality–technology can only be maintained with disciplined scheduling and data-driven cost tracking.

The MOL Campus is Hungary’s first high-rise tower building. Construction relied on a 2-metre-thick foundation slab, double-curved façade glazing and specialised MEP systems. During construction, wind shields were installed at high levels, and aviation regulations required lights to be placed at several points of the tower. Efficient organisation of logistics, workforce and materials was critical for cost effectiveness.